In the present manufacturing and style globe, precision and suppleness have grown to be crucial drivers of accomplishment. One of the supplies that stick out for their adaptability, laser cut acrylic has emerged being a entrance-runner. This versatile content is not merely common for its clear finish and Experienced visual appeal but will also for a way very well it integrates with modern plastic fabrication technologies. Across the UK, laser reducing plastic has grown to be a go-to procedure for corporations and creatives alike, revolutionising how plastic elements are formed and utilised.

Laser Slash acrylic refers to acrylic sheets which might be Slice utilizing higher-precision laser know-how. Unlike common cutting methods, laser reducing won't rely on Actual physical force or sharp blades. As an alternative, it employs a focused laser beam that melts, burns, or vaporises the material. This results in sleek, polished edges that want minimal to no write-up-processing. This sort of precision is important for purposes that need a flawless end, including retail shows, architectural versions, signage, and customised house décor.

Plastic fabrication in the UK has witnessed a marked change to laser-centered technologies over the past decade. As enterprises search for to reduce squander, lessen output expenditures, and speed up direct instances, the performance of laser reducing plastic has verified to become a valuable asset. No matter if it’s for building intricate styles, exact mechanical sections, or sleek merchandise prototypes, laser Slash acrylic delivers outcomes which have been tricky to achieve by way of other approaches.

Among the biggest benefits of laser reducing plastic is the opportunity to perform with an array of plastic supplies. Acrylic, also referred to as PMMA, is especially appropriate as a result of its laser-pleasant Homes. It reacts effectively to CO2 laser cutters, leading to crisp, crystal clear cuts with minimum distortion. In combination with acrylic, laser slicing may also be used on components like polycarbonate, PETG, ABS, and even PVC, While Many of these have to have Exclusive air flow a result of the fumes they emit throughout the slicing course of action.

Plastic elements used in laser reducing will not be limited to transparent sheets. They are available in a range of colours, finishes, and thicknesses, providing designers creative flexibility and useful overall flexibility. Frosted acrylic, mirrored acrylic, and fluorescent varieties offer you aesthetic appeal although retaining toughness and resistance to climate, UV light, and influence. This helps make them perfect for the two indoor and outdoor programs, from creative installations to purposeful industrial elements.

In the united kingdom, the plastic fabrication field is expanding steadily, supported by progress in technologies and raising demand for customised plastic methods. Companies in retail, construction, automotive, and professional medical sectors depend greatly on fabricated plastic parts which are light-weight, corrosion-resistant, and price-productive. Laser cut acrylic is frequently Employed in protective screens, device guards, gentle diffusers, and branded product or service parts, highlighting its wide utility.

One more reason for that escalating level of popularity of laser reducing plastic would be the pace at which creation is often scaled. After a structure is finalised applying CAD software, it may be fed straight to the laser cutter, making it possible for for quick fabrication. This digital workflow removes most of the measures affiliated with manual slicing or CNC machining. It’s especially useful for compact businesses and startups searching for swift turnarounds on personalized orders.

Plastic fabrication in the UK also Gains with the environmental pros that laser slicing can present. As the process is contactless and highly controlled, it generates less material squander in contrast to traditional reducing methods. Which has a increasing emphasis on sustainability, numerous United kingdom-based fabrication retailers are incorporating recycled or recyclable acrylic into their production strains, aligning with eco-conscious tactics.

When it comes to the selection of laser Minimize acrylic for just a job, it’s vital to get the job done with suppliers and fabricators who comprehend the nuances of laser reducing plastic. Elements like electrical power configurations, reducing speed, and content variety can considerably influence the caliber of the final product. Specialist plastic fabrication products and services in britain are well-Outfitted with the newest laser cutting machines and qualified specialists to make certain regular and superior-excellent outcomes.

Also, the look possibilities are unlimited with laser Reduce acrylic. Personalized designs, engraved logos, intricate cutouts, and layered constructions can all be obtained with exceptional precision. This has produced the fabric a favourite not only among industrial clientele but additionally with artists, architects, and item designers. No matter whether it’s creating illuminated signage or assembling elements for just a shopper gadget, laser reducing plastic delivers both of those kind and performance with each other within a seamless Remedy.

The flexibility of plastic products even more boosts their benefit in modern fabrication. From impact-resistant polycarbonate to lightweight polystyrene, Each and Laser Cutting Plastic every plastic kind brings exclusive Positive aspects for the desk. Laser Slash acrylic stays a staple resulting from its balance of visual appearance, effectiveness, and affordability.

As engineering carries on to evolve, so way too will the abilities of laser slicing in plastic fabrication. Improvements including multi-axis laser devices, hybrid cutting strategies, and automation integrations are previously beginning to redefine how we tactic materials processing. In britain and past, the demand from customers for precision-engineered plastic elements is likely to develop, with laser Slash acrylic primary the charge.

FAQs

What exactly is laser Slash acrylic used for?

Laser Slice acrylic is usually Employed in signage, Screen stands, lights fixtures, architectural designs, protective screens, and attractive merchandise as a consequence of its clear edges and Experienced finish.

Is laser chopping appropriate for all plastic products?

Not all plastic products are perfect for laser chopping. Acrylic, PETG, and ABS operate nicely, but resources like PVC require warning as a consequence of harmful fumes. It’s vital to check material compatibility with the laser cutter employed.

How thick can acrylic be for laser reducing?

Most CO2 laser cutters can deal with acrylic thicknesses starting from 1mm to 25mm. The cutting capability depends upon the laser electricity and the particular variety of acrylic.

Is laser slicing acrylic eco-friendly?

Laser cutting alone generates minimum squander, and using recyclable acrylic products can make the method additional eco-friendly. On the other hand, Electricity use and emissions need to be considered as Section of the overall environmental effects.

The place am i able to locate plastic fabrication expert services in the UK?

Plastic fabrication UK solutions are broadly obtainable, specifically in industrial hubs and on the net fabrication platforms. Lots of offer laser reducing plastic as aspect of their regular provider choices.

Hallie Eisenberg Then & Now!

Hallie Eisenberg Then & Now! Molly Ringwald Then & Now!

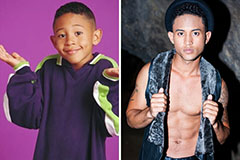

Molly Ringwald Then & Now! Tahj Mowry Then & Now!

Tahj Mowry Then & Now! Andrew Keegan Then & Now!

Andrew Keegan Then & Now! Dawn Wells Then & Now!

Dawn Wells Then & Now!